Turnkey Veneer Production Line: 0.001 mm Inline Thickness Control, GTH30‑32 Biomass Dryer and Maintenance Best Practices 2

Railway Maintenance and Upgrade Solutions — Practical Guide for Asset Owners

Executive summary

Modern, data-driven ballast maintenance couples rapid condition assessment with targeted equipment interventions — ballast cleaning, screening, tamping, undercutting and sleeper replacement — to extend track life, improve drainage and reduce costly renewals. A pragmatic program balances objective diagnostics (GPR, geometry profiling) with the right-sized equipment (modular excavator attachments, screening buckets, high‑vibration tampers) and a predictive maintenance workflow (condition database → digital twin → PdM scheduling). The result: fewer possessions, shorter on-track exposure, predictable lifecycle costs and measurable ROI.

📎 9074f674b6fb4c6ea5cf476f7155fa59.md

Key benefits

- Faster, objective condition assessment to prioritise interventions

- Lower lifecycle cost by delaying full renewal through targeted cleaning and tamping

- Reduced possession hours and improved field safety

- Measurable KPIs: geometry within class tolerances, fouling index, drainage restoration, fewer emergency repairs

Track condition assessment — decide the right intervention

Accurate diagnosis is the single most important step. Combine routine visual and geometry inspections with objective sensing to convert subjective judgement into actionable work packs.

Assessment methods

- Visual & routine geometry inspection: deflection, twist, gauge, surface irregularities and visible drainage problems.

- Ground Penetrating Radar (GPR): quantifies ballast fouling, ballast layer depth and trapped moisture to create objective fault maps and prioritise work (see Mínguez Maturana et al.).

- On-rail geometry measurement (profilers): locates dips, twists and longitudinal irregularities that require tamping or stoneblow.

Decision thresholds (practical guidance)

- Clean (ballast cleaning/screening) when GPR shows high fines or reduced ballast depth but sleepers and fasteners still provide adequate support.

- Replace ballast or sleepers where fouling penetrates deeply or structural elements (sleepers/fasteners) are degraded.

- Tamping where geometry errors are present but ballast is not irreparably fouled; stoneblowing or partial undercutting for localized void-fill.

Deliverable: an assessment report with GPS‑referenced priority map and recommended sequence: clean → screen → tamp → monitor.

Equipment solutions — selection criteria and procurement tips

Selecting the right equipment is about matching machine capabilities to the site, possession constraints and target KPIs.

Excavator ballast cleaning hopper

- Use: modular solution for excavator-based cleaning where dedicated trains are impractical.

- Key specs: capacity (e.g., 5.5 m³), robust high‑strength steel body, controlled discharge method for even lateral and bottom placement.

- Selection checklist: hopper capacity vs excavator flow rate, carrier compatibility, discharge configuration (side/under), quick‑coupler integration and wear parts availability.

- Procurement tip: request site compatibility details, operator training and warranty terms.

Premium rail excavator double‑head tamping

- Use: repacking ballast to restore geometry and resilience.

- Selection checklist: vibration frequency & amplitude, clamp force and type, GNSS/control integration and automation capability, carrier compatibility.

- Procurement tip: prioritise integrated geometry control and local operator training to ensure consistent quality.

Screening & separation (screening buckets)

- Use: on‑arm screening to separate reusable ballast from fines in smaller possessions or constrained sites.

- Selection checklist: bucket volume, screen aperture options, hydraulic flow requirements and spare screen availability.

- Procurement tip: trial apertures on a representative ballast sample and order spare screens.

Undercutters / plows / dustpan buckets

- Use: loosen ballast ahead of cleaning, shape shoulders and remove fouling in trenches and shoulders.

- Selection checklist: cutting depth, replaceable teeth, hydraulic flow match to carrier.

- Procurement tip: request field trials and match attachment to carrier hydraulic capacity.

Useful product images

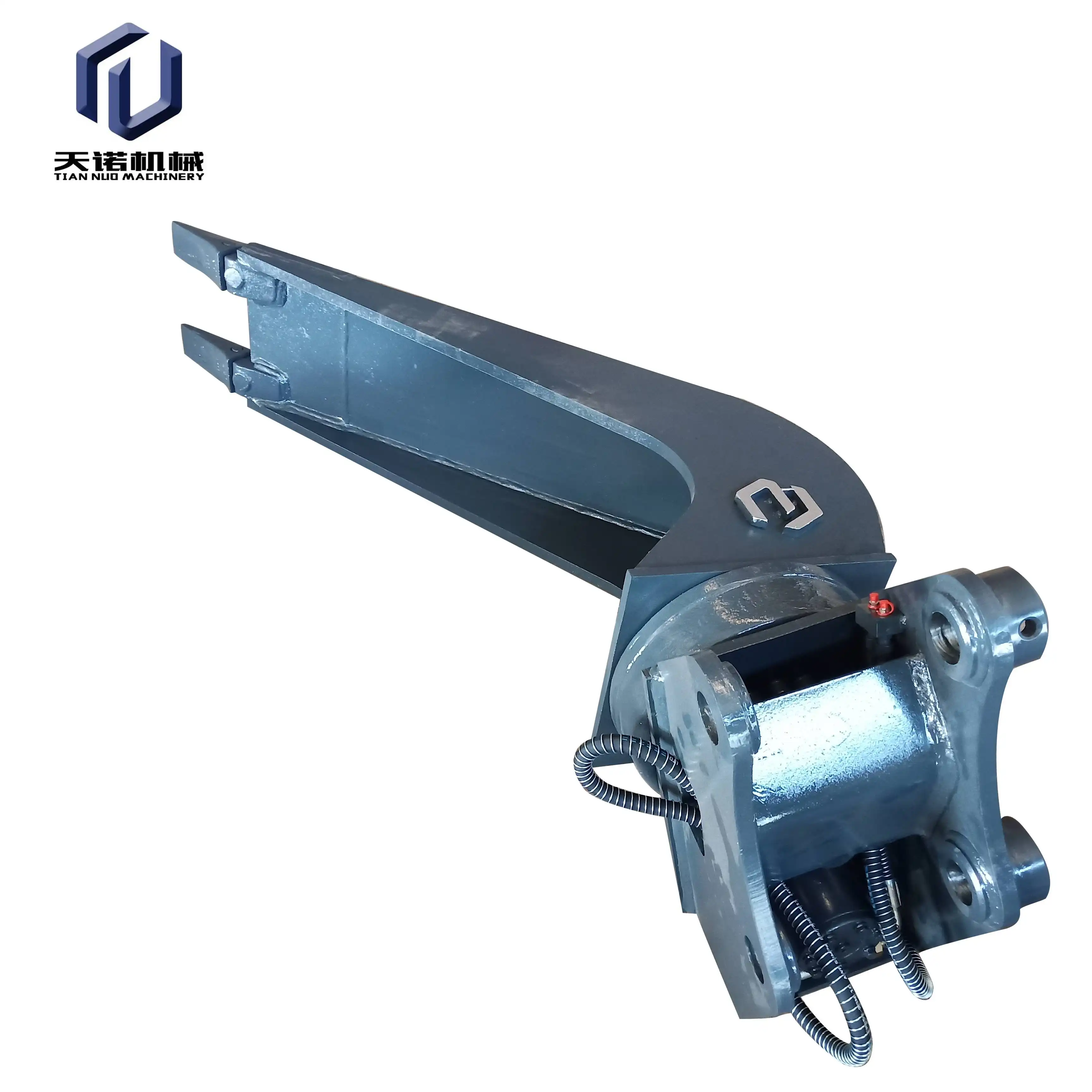

- Premium Rail Excavator Double Head Tamping Machine

- Ballast Blaster / Undercutter

Upgrade & retrofit checklist — lower CAPEX, faster benefits

Small, focused retrofits can expand an excavator fleet’s capability and deliver quick operational gains.

Recommended retrofits

- GNSS/GPS positional upgrade and improved control software for repeatable positioning.

- Vibration package tuning (adjustable frequency/amplitude) to match track class and ballast type.

- Hydraulic flow upgrades and quick‑coupler mods to support more attachments.

- Rail clamping safety kits, LED worklights and electrical safety improvements for safe night work.

Timeline & uptime

- Typical per‑machine retrofit: 1–3 weeks (hardware + software).

- Fleet rollout (assessment → pilot → full roll‑out): commonly staged over 60–120 days.

Preventive & predictive maintenance workflow

Shift from reactive to predictive maintenance by integrating surveys, condition databases and decision frameworks.

Workflow overview

- GPR survey and geometry profiling

- Condition database populated with GPR metrics, geometry deviation, tamping history and machine hours

- Asset model / digital twin (probabilistic state estimate) to forecast degradation and optimise interventions (see Torzoni et al.)

- PdM scheduling where thresholds trigger cleaning/tamping and possession windows are optimised

Data flows & KPIs

- Key signals: ballast fouling index, ballast depth, drainage index, geometry deviation rate and tamping intervals.

- Use these to minimise unplanned work, optimise spare parts provisioning and reduce lifecycle costs compared with reactive maintenance.

Case studies & cost comparison

Tiannuo field metrics show coordinated hopper + screening + tamping sequences achieving up to ~400 m/h in favourable conditions — a material acceleration for short possessions. Targeted cleaning campaigns postpone full renewal cycles and reduce possession hours compared to wholesale ballast replacement, delivering lower lifecycle costs when diagnostics are correct and work sequencing is optimised.

Cost insight (practical view)

- Ballast cleaning + tamping campaigns: moderate CAPEX, lower possession time, defers large renewal costs.

- Full ballast replacement: high CAPEX and much longer possessions; appropriate when ballast or sleepers are beyond repair.

Implementation timeline, training & support

Recommended phased plan (60–120 days)

- Assessment & GPR survey (2–3 weeks)

- Pilot equipment deployment and operator training (2–4 weeks)

- Roll‑out and retrofit schedule (4–8 weeks)

- Ongoing PdM and spare parts programme

Training scope

- Operator handling and safe clamping/tamping procedures

- Control system operation (GNSS, geometry references)

- Scheduled maintenance, wear part replacement and diagnostic checks

Support

- Warranty options, local spare parts provisioning and field technical guidance are essential to maintain productivity and ROI.

Selected FAQ

Q: How much does a ballast cleaner cost?

A: Costs vary by capacity, automation and localization. Request a tailored quote including warranty and spare parts at arm@stnd-machinery.com.

Q: When to tamp vs stoneblow?

A: Tamping repacks ballast to correct geometry when ballast is serviceable. Stoneblowing fills voids with small stonechips and is complementary for void‑specific interventions. Use GPR to guide the choice.

Q: What hourly output can I expect?

A: Outputs depend on site conditions and possessions. Tiannuo reports up to ~400 m/h in optimised sequences; restrictive sites will yield lower rates.

Q: Lead times & support?

A: Delivery and retrofit lead times depend on scope—contact arm@stnd-machinery.com or +86 17605473938 for details.

Conclusion

A combined strategy — GPR‑backed assessment, right‑sized modular equipment and a predictive digital‑twin/PdM workflow — delivers measurable reductions in life‑cycle costs, shorter possessions and safer field operations. Start with a targeted survey and a small pilot retrofit to validate ROI, then scale capacity with retrofits and operator training.

About Tiannuo & contact

Tiannuo supplies engineered attachments and machines designed to reduce track downtime and raise field productivity. Selected products include: Premium Rail Excavator Double Head Tamping Machine; Excavator ballast cleaning hopper; Ballast Blaster Undercutter; Railway Sleeper Changer.

Contact: arm@stnd-machinery.com | tn@stnd-machinery.com

Phone: +86 17605473938

WhatsApp: https://api.whatsapp.com/send?l=en&phone=8617865506382

Inquiry: https://www.stnd-machinery.com/contact-us

References

- Mínguez Maturana, R., Duclos Bautista, B., Aguacil, Á. A., & Rodríguez Plaza, M. (Year). Preventive Maintenance of Railway Infrastructures using GPR — methodology and applied case studies. Journal/Conference.

- Torzoni, M., Tezzele, M., Mariani, S., Manzoni, A., & Willcox, K. E. (2023). A digital twin framework for civil engineering structures — predictive maintenance and asset management approaches. arXiv/Technical Report.

- Vale, C., Ribeiro, I., & Calçada, R. (Year). Integer programming to optimize tamping in railway tracks as preventive maintenance. Journal of Transportation Engineering.

- Arcieri, G., Hoelzl, C., Schwery, O., Straub, D., Papakonstantinou, K. G., & Chatzi, E. (2023). POMDP inference and robust solutions via reinforcement learning for railway maintenance planning. arXiv.

- Furukawa, A. (2016). Recent tendencies in ballasted track maintenance — integrated machine scheduling and system upgrades. Quarterly Report Rtri.

- Nunez, J. (2013). Ballast maintenance for the best roadbed — practical guidance for long‑term performance. Railway Track and Structures.

- Khouy, I. A. (2013). Cost‑effective maintenance of railway track geometry: a shift from safety limits to maintenance limits — lifecycle modelling and optimization.