How to Choose a Tray Dryer (1–4 Layers): Capacity, Heat Source, and ROI

Choosing the right tray dryer is a practical, engineering-led decision with clear commercial stakes. The fastest way to narrow options is to align five drivers from the start: target throughput (kg/hr or m²/hr), product heat sensitivity, space constraints (floor and ceiling), available utilities (steam, gas/LPG, electric, biomass), and budget envelope across CAPEX and OPEX. Once these are defined, it becomes straightforward to compare a single layer tray dryer with multi-layer tray dryer configurations on throughput, drying uniformity, and lifecycle costs.

Layer configurations: what changes from 1 to 4 layers

- Single layer tray dryer: Delivers the best drying uniformity, with simple controls and fast R&D turnarounds. It’s typically the lowest base CAPEX and the safest choice for heat-sensitive or high-value products, pilot trials, and early process development.

- Two layers: Good fit for small production runs where footprint is limited. Airflow zoning becomes slightly more complex; however, overall operation remains manageable and efficient.

- Three–four layers: Suitable for compact, mid-scale production when floor space is constrained. Throughput scales roughly 2–4× per cabinet footprint, but CAPEX rises, control logic becomes more involved, and well-designed airflow zoning is critical to preserve uniformity across layers.

Rules of thumb to benchmark capacity: assume typical tray area of about 0.4–1.0 m² per tray (vendor dependent), then scale throughput by product moisture load and airflow. If the product is heat sensitive or the batch is high value, a single layer tray dryer is often the safer bet; if you need steady mid-volume output with tight floorspace, consider 3–4 layers with robust airflow zoning.

Quick sizing and energy math you can trust

- Water to remove per batch (kg) = wet mass × moisture change.

- Required capacity (kg/hr) = water per batch ÷ cycle time (hr).

- Energy estimate = kg water/hr × 1–3 kWh/kg water evaporated (depends on dryer design, recirculation, and heat recovery).

Example: If you need to remove 40 kg of water in a 4-hour cycle, that’s 10 kg/hr. At 2 kWh per kg, expect about a 20 kW continuous thermal load. With electricity at $0.10/kWh, energy costs are roughly $2.00/hr or $0.20/kg water removed. Perform the same comparison against gas/LPG or steam by converting to common units and local tariffs.

Heat source tradeoffs: match utilities to control and cost

- Steam: Excellent temperature control and sanitation, ideal for food and pharma settings with existing boiler infrastructure. Condensate handling adds complexity, but control is top-tier.

- Gas/LPG: Often the lowest fuel cost at scale. Requires proper combustion exhaust and emissions management; well-suited to higher evaporation loads.

- Electric: The simplest to install with precise control and no combustion byproducts. OPEX can be higher where electricity rates are elevated; a strong choice for small to mid-sized plants or cleanroom needs.

- Biomass: Attractive where low-cost biomass is readily available. Expect added storage, handling, and emissions considerations; good for certain regional contexts.

Ask every vendor for energy per tonne of water removed (kWh/tonne or MMBtu/tonne), and for heat-recovery options (recirculation percentage, economizers, insulation levels). These answers drive OPEX and payback more than nameplate power alone.

Automation levels and what they mean for ROI

- Manual loading: Lowest CAPEX, but higher labor demand and ergonomic risk.

- Semi-automatic: Hoists, mechanized trolleys, or lifts cut labor and improve safety with modest incremental CAPEX.

- Fully automated: Conveyorized infeed/outfeed with PLC/SCADA and upstream/downstream integration delivers high throughput, tight repeatability, and lower unit costs at medium-to-high volume—but with the highest CAPEX.

Illustrative payback: If semi-automation adds $50k in CAPEX and saves $20k/year in labor and quality-related scrap, payback is ~2.5 years. A more extensive automation package at $150k that saves $60k/year also pays back in ~2.5 years. Your actuals will hinge on wage rates, shift patterns, reject costs, and planned utilization.

What to request before purchase and at acceptance

- Technicals to request: per-layer drying area (m²), airflow per tray (m³/hr), measured energy per tonne water removed, heater specs, heat-recovery approach, PLC/SCADA I/O list, materials (e.g., 316L for food/pharma), CIP options, and vendor test-run protocol.

- On-site acceptance tests: map drying uniformity across trays and layers, validate cycle time, measure specific energy consumption, and verify product quality criteria (including microbial parameters for food/pharma).

Why vendor capability strongly influences outcomes

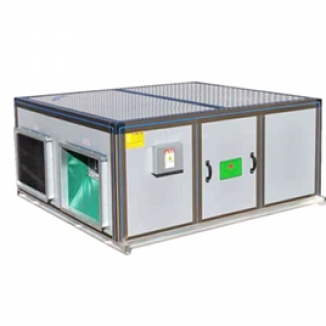

A tray dryer is only as good as its control system and quality assurance. Shine Health’s manufacturing context—combining automated central control, in-house R&D, and dedicated QC laboratories—illustrates how industrial automation and disciplined QA lower integration risk. For multi-layer systems, consistent airflow management, stable thermal profiles, and traceable control logic are what protect uniformity, repeatability, and ultimately ROI.

A simple decision matrix you can use today

- R&D trials, small batches, heat-sensitive products → Favor a single layer tray dryer for maximum control and uniformity.

- Limited floor space with modest throughput needs → Consider 2–3 layers with zoned airflow and basic automation.

- Compact medium-scale production with labor pressure → Choose 3–4 layers, evaluate heat recovery and higher automation; model CAPEX vs. OPEX before award.

For a procurement checklist, a vendor RFQ template, or an ROI spreadsheet calibrated to your energy tariffs and target kg/hr, contact Shine Health’s technical team at info@sdshinehealth.com or submit a request at https://www.sdshinehealth.com/contact-us.html. You can also reach us on WhatsApp for rapid support: WhatsApp.

References

- Argo, B. D., Sandra, S., & Ubaidillah, U. (2018). Mathematical modeling on thin layer drying kinetics of cassava chips in a convective tray dryer heated by gas burner. Journal of Mechanical Science and Technology, 32(7), 3313–3320. https://doi.org/10.1007/s12206-018-0646-2

- Delgado-Plaza, E., Peralta-Jaramillo, J., Quilambaqui, M., et al. (2019). Thermal evaluation of a hybrid dryer with solar and geothermal energy for agroindustry. Applied Sciences, 9(19), 4079. https://doi.org/10.3390/app9194079

- Khathir, R., Nelwan, L. O., & Sucipta, M. (2024). Performance of greenhouse effect–hybrid type tray dryer in drying cloves. IOP Conference Series: Earth and Environmental Science, 1302(1), 012106. https://doi.org/10.1088/1755-1315/1302/1/012106

- Murugan, P., Dhanushkodi, S., Sudhakar, K., & Wilson, V. H. (2021). Industrial and small-scale biomass dryers: An overview. Energy Engineering, 118(6), 441–459. https://doi.org/10.32604/EE.2021.013491

- Zhang, M., Bhandari, B., & Fang, Z. (2017). Handbook of Drying of Vegetables and Vegetable Products. CRC Press. https://doi.org/10.4324/9781315152677

- Afonkina, V., Popov, V. M., Levinsky, V., & Medvedev, A. (2023). Technical-and-economical assessment of tray-type installation for dairy starter cultures’ drying. Tekhnika i Tekhnologii v Zhivotnovodstve, 3, 92–101. https://doi.org/10.22314/27132064-2023-3-92

- Dute, S. N., Bijwe, M. P., & Pawar, D. B. (2025). Design modification of tray dryer to increase efficiency. International Journal of Advanced Research in Science, Communication and Technology, 5(2), 1–7. https://doi.org/10.48175/ijarsct-23239